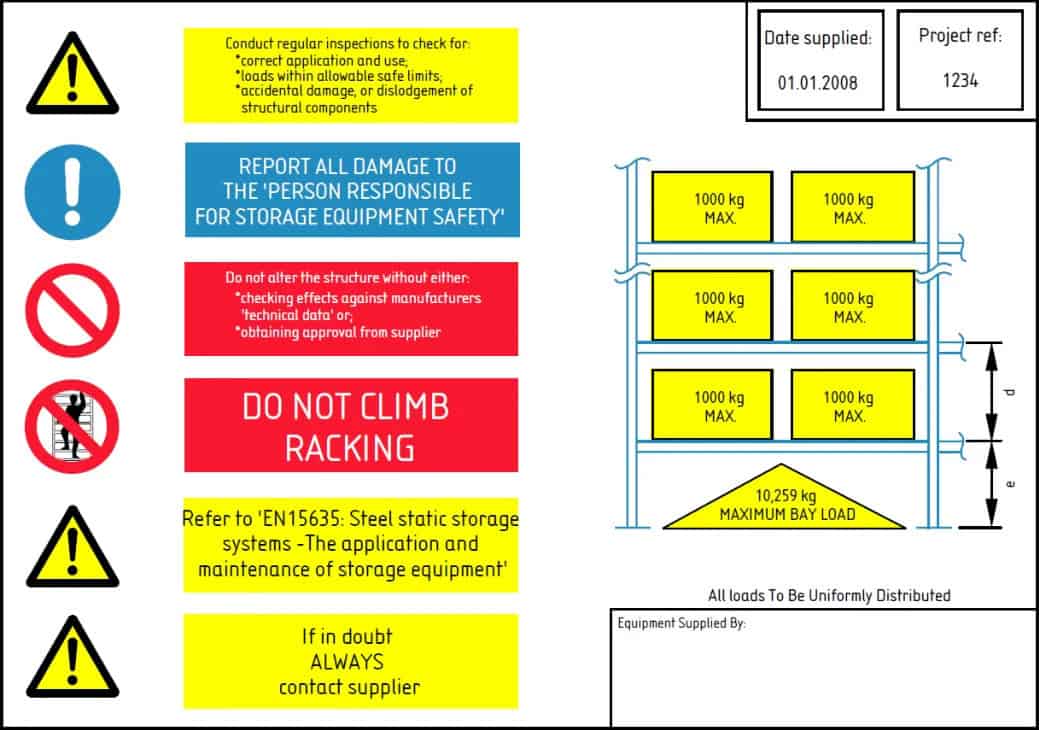

For typical loads on rack structures, the load of a single item at the “characteristic load” level is not a fixed statistical value; instead, it must be specified according to the day-to-day operation of the project. Throughout the lifecycle of the racks, the load on the structure must be monitored through warehouse management to ensure it does not conflict with the usage conditions assumed during the design phase.

Key Specific Loads on Racks

- Storage Unit Load

- Dynamic Load from Placement Operations

- Loads Caused by Access Equipment Supported or Guided by the Racks (e.g., stackers)

- Floor Load Directly Supported by the Racks

Correctly accounting for loads in rack structure design is essential for ensuring safety. Therefore, at the start of the design phase, project planners and end users need to be guided appropriately to accurately determine load information for the project.

Forklift Load

For racks designed to accommodate forklift operations, the design does not consider the impact of forklift collisions. This is because cold-formed thin-walled rack uprights and beams cannot withstand such significant horizontal forces.

However, cold-formed thin-walled steel racks can still be operated safely (despite not being impact-resistant) if the following conditions are met:

- Forklift operators receive training and guidance on operating in the rack environment.

- Adequate operational space is ensured, including sufficient aisle clearance and space between storage units and racks.

- Independent impact protection is installed at all aisle and passageway corner columns, with additional protection recommended elsewhere.

- A designated person is assigned responsibility for the safety of storage equipment (racks).

- Regular, systematic checks are conducted for rack damage, with immediate unloading in case of red-level damage.

- Regular, systematic checks ensure that actual use aligns with the user manual.

Analyzing and identifying potential causes of damage helps reduce (or ideally eliminate) the likelihood of recurrence.

Responsibilities of Planners, Suppliers, and Users

Beyond load considerations, the actual safety level of the structure also depends on an appropriate management system that ensures operational procedures align with the design phase considerations. For racks, personnel factors (operation and maintenance) are constant additional influences on structural safety. Therefore, rack suppliers need to communicate operational guidelines to users, and users must follow these guidelines and conduct regular maintenance—both aspects are equally important.