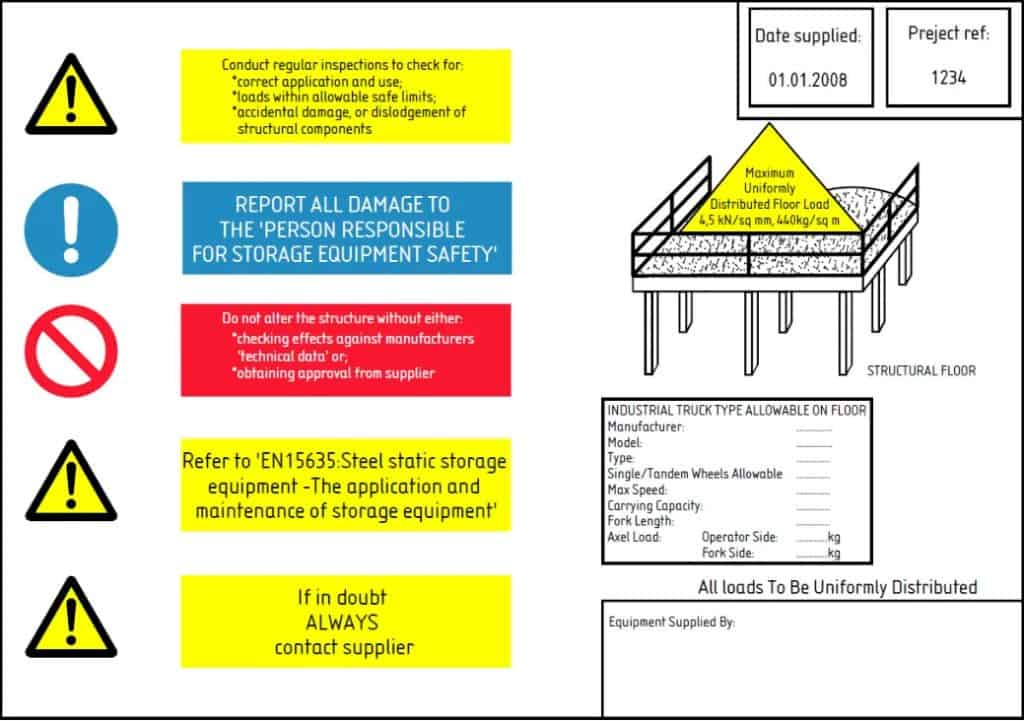

Why Load Capacity Sign is Necessary

Whenever steel structure racks are designed, manufactured, and installed, the original signed engineering documents detailing the maximum safe load capacity of the racks should be kept intact. However, these documents are often stored in filing cabinets, making them difficult for personnel responsible for operating and maintaining the racks to access. Without easy access to the original design information, operators frequently make structural changes to the racks or use pallet loads that exceed the maximum safe capacity. This unknowingly creates a potentially unsafe operation and working environment.

To address this, rack design and usage standards generally specify that the rack owner is responsible for placing load warning signs in one or more prominent locations.

What Info Should be Showed

Typically, rack manufacturers provide load warning signs for the racks. A best practice is to place one sign per aisle for each rack arrangement, as different rack structures may be arranged within the same aisle. Although not required by standards, most rack manufacturers include their logo, contact information, manufacturing or installation date, and other specific identifiers or detailed safety information on the load warning signs.

- The maximum allowable weight for each storage unit and/or the maximum uniformly distributed load per level.

- The maximum total load weight per rack bay.

- Identification of positions where stacked storage is permitted.

Attachment