Wondering how to ensure your warehouse racks are secure and stable? Pallet rack safety pins are the key. In this article, we’ll explore what they are, why they matter, and how to use them properly.

Key Takeaways

Pallet rack safety pins, also known as locking pins, are essential for securing beams to vertical supports in a racking system, preventing dislodgment and enhancing warehouse safety.

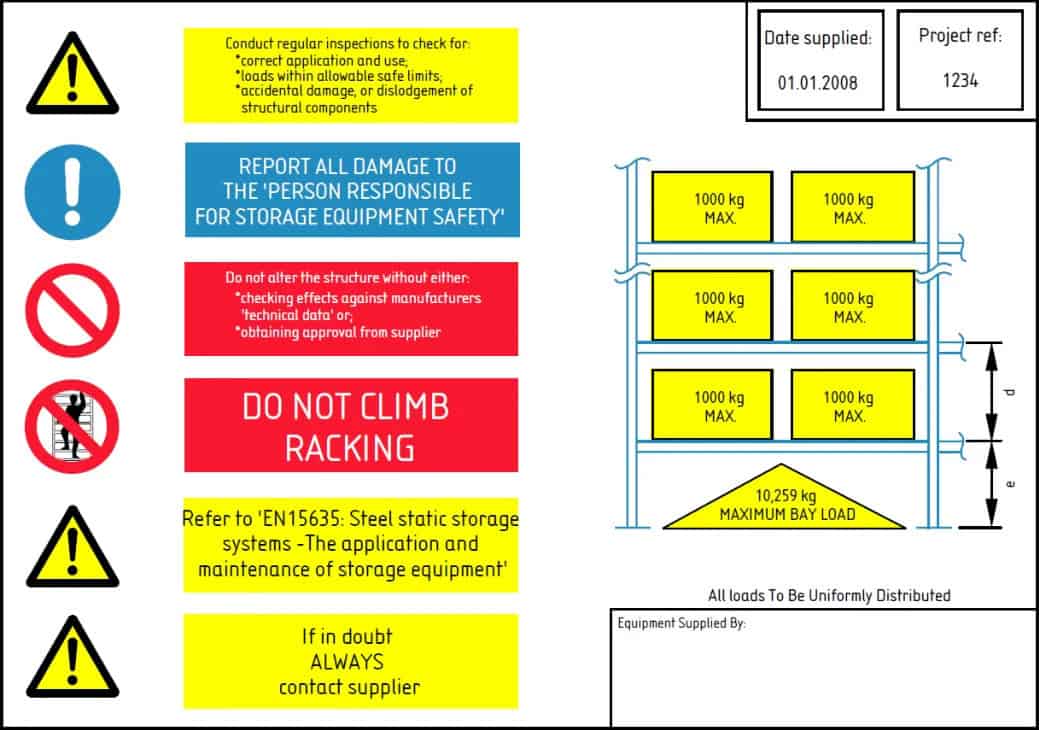

Regular maintenance, inspection, and adherence to safety standards are crucial for ensuring the effectiveness of safety pins and the overall stability of pallet racking systems.

Proper installation techniques and training in material handling are vital for maximizing rack stability and minimizing accident risks in warehouse operations.

Understanding Pallet Rack Safety Pins

Pallet rack safety pins are indispensable components designed to secure the beams of a racking system to the vertical uprights. This ensures the stability and safety of the entire racking system, preventing accidents due to dislodged beams. These safety pins, often referred to as beam locks, play a vital role in warehouse safety by securing the beams to the upright frame, thus preventing them from falling during loading and unloading operations.

We’ll explore what pallet rack safety pins are, the different types available, and the materials used to manufacture them. This knowledge will help you understand their importance and contribution to warehouse safety.

What Are Pallet Rack Safety Pins?

Pallet rack safety pins, also known as locking pins, are devices specifically designed to secure beams to vertical supports in a racking system. Their primary function is to prevent the dislodgment of beams, ensuring that the structure remains stable and secure. These pins utilize mechanisms such as gravity and friction to hold the pallet rack beams in place effectively.

There are various types of these devices, including clips and bolts, that serve the same purpose of securing beams to the uprights of pallet racks. Understanding the function and types of pallet rack safety pins allows you to appreciate their critical role in maintaining a safe warehouse environment.

Types of Safety Pins

When it comes to pallet rack safety pins, there are several types to consider, each serving unique purposes. Permanent safety pins provide a fixed solution, ensuring beams are securely attached within the racking system. On the other hand, removable safety pins offer flexibility, allowing for quick adjustments to the racking system.

Specific examples include the Sturdi-Bilt Wedge Lock, a hook-like clip used for securely attaching beams to uprights, and Rifle Slide Locks, which allow for easy engagement and disengagement directly from the beam’s face.

Materials Used in Safety Pins

The choice of materials for pallet rack safety pins is critical for their durability and effectiveness. Most safety pins are made from steel due to its strength and durability, ensuring they can withstand the demands of a busy warehouse environment. This material choice helps maintain the integrity of the racking system, providing long-term safety and stability.

The Importance of Using Safety Pins in Pallet Racking Systems

The importance of using pallet rack safety pins cannot be overstated. These small components are essential for securing pallet rack beams, preventing accidental dislodgment that could lead to serious accidents and injuries. Properly installed safety pins ensure the overall stability of the racking system, providing peace of mind in a high-stakes environment like a warehouse.

Moreover, regular checks and maintenance of these safety pins are vital. Damaged or worn safety pins should be replaced immediately to uphold safety standards and maintain the structural integrity of the pallet racking system. Selecting the correct safety pins compatible with your racking system’s design and ensuring they meet the required specifications for load capacity is crucial.

Preventing Beam Dislodgment

One of the primary functions of safety pins is to prevent the accidental dislodgment of beams during loading and unloading activities. These pins lock the beams in place, significantly reducing the risk of pallets falling from racks. This action is crucial in stopping beams from unintentionally lifting away from the rack, thereby preventing potential falls of pallets and injury.

Common errors, such as having loose or missing safety pins, can compromise the stability of the pallet rack. Ensuring all pins are properly seated and compatible with the racking system is essential to avoid failures during operations. Each safety pin should be assessed for its ability to withstand specified forces, typically around 2000 pounds per pin, to maintain the integrity of the racking system.

It’s important to note that safety pins are intended to prevent the disconnection of beams rather than support loads, highlighting the need for correct load assessment in rack configurations. By understanding the critical role safety pins play in preventing beam dislodgment, you can better appreciate their importance in maintaining a safe warehouse environment.

Compliance with Safety Standards

Compliance with safety standards is a non-negotiable aspect of warehouse operations. Regulatory guidelines, such as the SEMA Code of Practice and RMI standards, mandate the use of safety pins in pallet racking systems. These standards outline the necessary safety measures to be implemented, ensuring that pallet racks are safely secured and reduce the risk of accidents.

Manufacturers must adhere to these codes by installing safety pins in all racking systems that are loaded using material handling equipment. This compliance not only ensures the protection of employees but also helps in maintaining a cost-effective and efficient warehouse operation by minimizing risks and potential downtime due to accidents.

How to Properly Install Pallet Rack Safety Pins

Proper installation of pallet rack safety pins is crucial for ensuring the stability and safety of your racking system. Begin by assembling and anchoring the upright frames correctly as per the manufacturer’s guidelines. The installation of pallet rack drop pins can typically be done without tools, making the process straightforward and user-friendly.

This guide provides a step-by-step process for installing safety pins and highlights common mistakes to avoid. Following these instructions will ensure your pallet rack safety pins are installed correctly and effectively.

Steps for Installing Safety Pins

The first step in installing pallet rack safety pins is to align the holes in the beam and upright. This alignment is essential for securing the structure. Once the holes are properly aligned, insert the safety pins through the beam and the upright frame to provide stability. Ensure that the safety pin is pushed fully through to secure the connection between the beam and frame.

Following these steps ensures that your pallet racking system remains stable and secure, preventing accidental dislodgment of beams during operations.

Common Installation Mistakes

One frequent mistake during installation is failing to fully engage the safety pin, which can lead to a weak connection. Improperly aligned uprights can also result in rack instability and increased risk of failure during operation. Neglecting to securely fasten safety pins can result in beams detaching, posing serious risks in a warehouse environment.

To avoid these common errors, always ensure that the holes are correctly aligned before inserting the safety pins. To secure Ridg-U-Rak spring clips and safety clips, pinch the sides together, insert into the upright, and release in aligning holes.

Attention to these details helps maintain a safe and efficient warehouse operation.

Maintenance and Inspection of Safety Pins

Regular maintenance and inspection of pallet rack safety pins are essential for preventing accidents and ensuring the long-term stability of your racking system. Utilizing racking safety pins significantly reduces the risk of racking collapse, which can occur from beams being dislodged. These pins provide additional security to prevent beams from disconnecting under load, enhancing overall safety.

Implementing comprehensive safety checks and maintenance schedules can significantly reduce the risk of accidents in warehouses. Regular visual assessments help spot any damage or deterioration in safety pins, ensuring they remain effective. Incorporating these practices into your warehouse operations helps maintain a safe working environment.

Routine Inspections

Routine inspections are crucial for ensuring the safety and functionality of pallet rack safety pins. During these inspections, check that safety pins are properly installed at the connection points between beams and uprights. Look for any damage or wear to safety pins, along with other components like beams and uprights.

Neglecting to inspect safety pins can lead to potential risks, including beam dislodgment and collapse of the racking system. By incorporating regular inspections into your warehouse maintenance protocols, you enhance overall safety and ensure that your pallet racking system remains stable and secure.

Replacing Damaged Safety Pins

Damaged safety pins in pallet racking systems must be replaced promptly to maintain structural integrity and prevent accidents. To replace damaged safety pins, unload the affected rack section and assess for any additional damage before installing new pins. Using appropriate repair kits and trained technicians is essential for safely replacing damaged safety pins in pallet racks.

Addressing damaged safety pins immediately prevents potential racking failures and ensures the continued safety of your warehouse operations.

Evaluating Load Capacity and Compatibility

Understanding the load capacity of safety pins is crucial for the stability of pallet rack beams. Each safety pin needs to withstand an upward force of at least 2000 pounds to ensure safety during operations. Assessing compatibility of safety pins with existing racking systems includes confirming that each pin can endure the necessary load without failure.

Evaluating load capacity and compatibility ensures that your racking system remains secure and functional.

Enhancing Warehouse Safety Beyond Safety Pins

While pallet rack safety pins are vital for maintaining the stability of racking systems, there are additional measures you can take to enhance overall warehouse safety. Implementing a safety-first culture can significantly reduce accidents and injuries. Maintaining clear aisles in a warehouse reduces the risk of trip and fall accidents and facilitates quicker emergency access.

Proper training for material handling and implementing safety protocols are essential components of a comprehensive warehouse safety strategy. These measures ensure that employees are equipped with the knowledge and skills to handle materials safely and responsibly.

Proper Training for Material Handling

Proper training in material handling is essential for warehouse safety as it equips staff with knowledge and skills to handle materials effectively and responsibly. Warehouse staff should be trained in techniques such as lifting heavy items correctly to avoid injury and maintaining a clear path while transporting goods.

Implementing proper material handling techniques not only reduces the risk of accidents but also enhances overall efficiency in warehouse operations.

Implementing Safety Protocols

Developing and implementing safety protocols is crucial for maintaining a safe warehouse environment. Training employees on ergonomic lifting techniques can prevent musculoskeletal injuries during manual handling. Effective training programs should include hands-on practice to reinforce proper material handling techniques. Establishing clear communication channels for reporting safety concerns enhances employee engagement in safety protocols.

Regularly updating safety protocols based on incident analysis can lead to continuous improvement in warehouse safety. Fostering a culture that encourages timely reporting and repair of any racking system damage helps maintain overall safety and efficiency.

Summary

In summary, pallet rack safety pins are an essential component in maintaining the stability and safety of racking systems in warehouses. Understanding their types, proper installation methods, and the importance of regular maintenance and inspections can significantly reduce the risk of accidents. Additionally, implementing proper training and safety protocols further enhances warehouse safety.

By prioritizing the use of pallet rack safety pins and fostering a safety-first culture, you can ensure a secure and efficient warehouse operation. Remember, the safety of your employees and the integrity of your racking system depend on these small but mighty components.

Frequently Asked Questions

What are pallet rack safety pins and why are they important?

Pallet rack safety pins are essential locking devices that secure beams to vertical supports, preventing dislodgment and maintaining the stability of the racking system. Their importance cannot be overstated, as they significantly enhance safety in storage environments.

What types of pallet rack safety pins are available?

Pallet rack safety pins are available in both permanent and removable types, such as Sturdi-Bilt Wedge Lock and Rifle Slide Locks, each designed for specific applications within pallet racking systems. It is essential to choose the appropriate type to ensure effective safety and functionality.

How should pallet rack safety pins be installed?

Pallet rack safety pins should be installed by aligning the beam holes with the punch holes in the frame and inserting the pins fully to ensure a secure connection. This process is critical for maintaining the stability and safety of the rack system.

Why is regular maintenance and inspection of safety pins necessary?

Regular maintenance and inspection of safety pins are crucial to prevent beam dislodgment and maintain the structural integrity of the racking system. Ensuring that these pins are properly installed and undamaged directly contributes to overall safety.

What additional measures can enhance warehouse safety beyond using safety pins?

Enhancing warehouse safety can be achieved by providing proper training for material handling, implementing safety protocols, maintaining clear aisles, and promoting a safety-first culture. These additional measures significantly reduce accidents and improve overall operational efficiency.