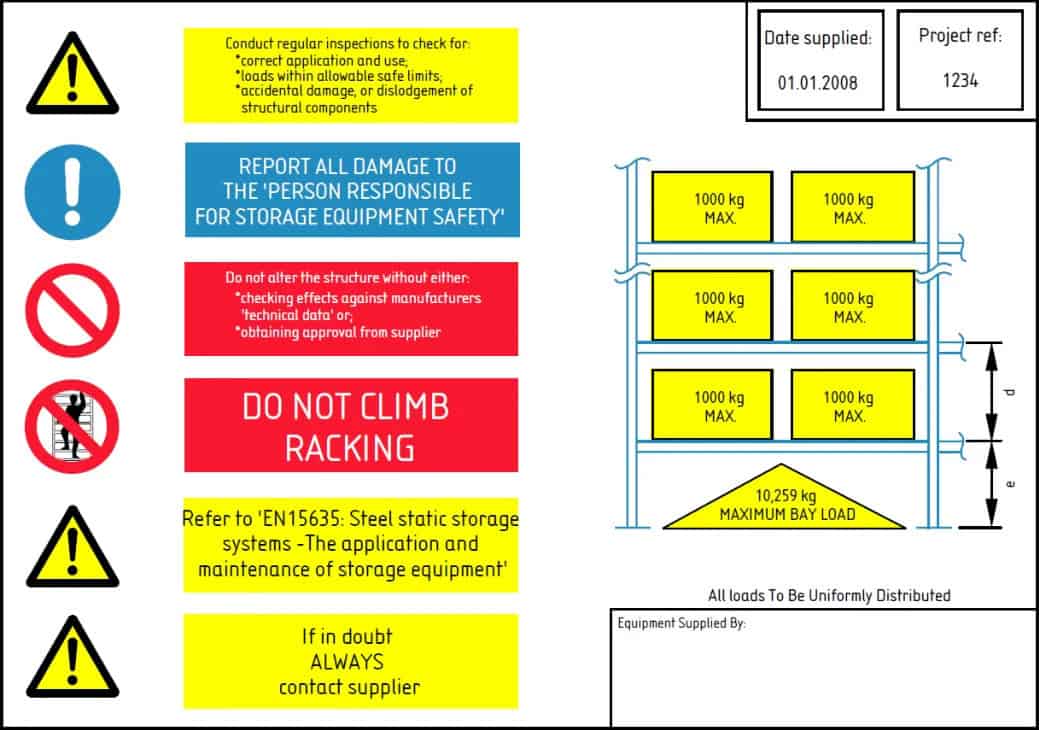

Many warehouses have potential safety hazards. For example, when the height of the storage grid does not match the height of the goods or when the forklift operator makes an operating error, the goods may hit the upper beam, causing the upper beam hanging bracket to unhook and the beam to fall, resulting in safety accidents such as goods falling or even hitting workers. Or when a forklift moves a storage unit, if it is lifted too high, it will hit its upper beam, thereby exerting an upward thrust on the beam. Therefore, in the design of beam-type warehouse racking, a safety pin is required to be set between the beam end hanging plate and the column. When the accidental thrust is transmitted to the beam-column node, the shear resistance of the safety pin resists it, thereby preventing the beam from falling out of the column hole.

Design Standard of Safety Pin

The safety pin is designed as a shear-resistant part. The relevant regulations stipulate that the safety pin should be able to resist the upward pull force of 5kN to ensure that the beam hanging plate does not unhook. Therefore, the safety pin can only play a role in preventing the beam from falling when it is subjected to an upward pull force within 5kN, but in practice, it often generates a force far greater than 5kN.

Design Concept of Pallet Racking Safety Pin

Considering that the shear force caused by the accidental upward force applied by most forklifts will exceed 5kN, the design concept of the safety pin is to allow it to be sheared or failed under the action of accidental excessive force, and the crossbeam will be pulled out of the column hole. In this way, the consequences of the accident will be limited to the collapse of a group of storage units. If the crossbeam cannot be pulled out of the column hole, the consequence is to tear the wall of the column hole, resulting in the destruction of the entire column, followed by the collapse of all the crossbeams connected to the column, and then to the adjacent columns and then the collapse of the entire row of racking along the aisle direction. This is the so-called structural continuous collapse.

Therefore, the shear resistance of the safety pin must not only meet the minimum requirements of the standard to ensure that the beam cannot fall out at will, but also ensure that the beam can fall out under the action of large accidental forces to avoid damaging the column.

Do Not Use Screws Instead of Safety Pins

Although the bolt fixing method can ensure that the beam and the column are not separated, when the force on the beam is too large or occurs frequently, since there is almost no looseness between the beam and the column, the upward pull force on the beam will be transmitted to the column, causing damage to the column or even causing collapse, which is a more serious safety accident than the beam falling off.

Conclusion

- The relevant regulations stipulate that the safety pin should be able to resist the upward pull force of 5kN.

- The shear resistance of the safety pin must not only meet the minimum requirements of the standard but also ensure that the beam can fall out under the action of large accidental forces to avoid damaging the column.

- Don’t use screws to replace safety pins.