What is VNA Racking System?

The Very Narrow Aisle (VNA) Pallet Rack is an adaptation of the standard adjustable pallet racking system, but compressed into a very small area, creating a high-density storage system that can increase warehouse capacity without enlarging the space.

In very narrow aisle pallet racking systems, pallet racks are closer together than other pallet racking solutions because they use side loading forklifts for loading and unloading – narrowing the aisles and ensuring efficient use of storage space. Product storage and warehouse space utilization are maximized. VNA aisles are typically 6.6 feet wide, offering 44% more floor space than selective pallet racking systems.

Pros and Cons Of VNA Racking System

Advantages of VNA Pallet Racking:

- It provides 100% accessibility

- It provides good stock rotation

- It can maximize the warehouse storage place by reducing aisle space

- It decreases the rate of product damage

- This System reduces the chances of picking errors occur

Disadvantages of VNA Pallet Racking:

- This system requires a special lift truck to operate which is extra cost

- Two forklifts cannot pass in the same aisle at the same time

- Requires a “hand-off” of inventory from the VNA forklift to a dock working forklift on outbound, and the opposite for inbound

Components Of VNA Racking System

Similar to standard or wide aisle racking systems, the main components used to create the structure include the frame, columns and beams. In addition, the forklift needs to be guided, which can be in the form of mechanical or wired guidance. Mechanical guidance is a track that runs along the exterior of the structure and serves as a barrier between the truck and the structure. The slender ram is equipped with additional flip-up wheels that run along the track without the truck itself making contact with the track. Wired guidance consists of a slender electromagnetic cable that runs centered along the aisle floor and connects to a truck sensor to guide it.

How Does VNA Racking Work?

Since the aisle width between high rows of shelves is very narrow, this is a solution to maximize storage capacity by utilizing as much of the floor and height space features as possible. Compared to standard wide aisle racking systems, the VNA racking solution provides more storage capacity with additional overhead pallet positions and additional rows.

VNA racks do require specialized forklifts, as the aisle width is too narrow for standard trucks to operate. Since there is much less space between racks, VNA trucks are designed to work on long straight lines guided by rails or hidden wired rails. These trucks can reach higher heights and work faster than conventional trucks, which can increase productivity and efficiency while saving time.

What Warehouse Fits VNA Racking?

VNA racks are the perfect solution for any operation looking to utilize as much height space as floor space. This solution enables growing businesses to accommodate increased inventory levels only by utilizing redundant height space. Customized VNA racking systems are designed to support individual operations, inventory needs and maximize specific space utilization.

Is It Safe To Use VNA Racking?

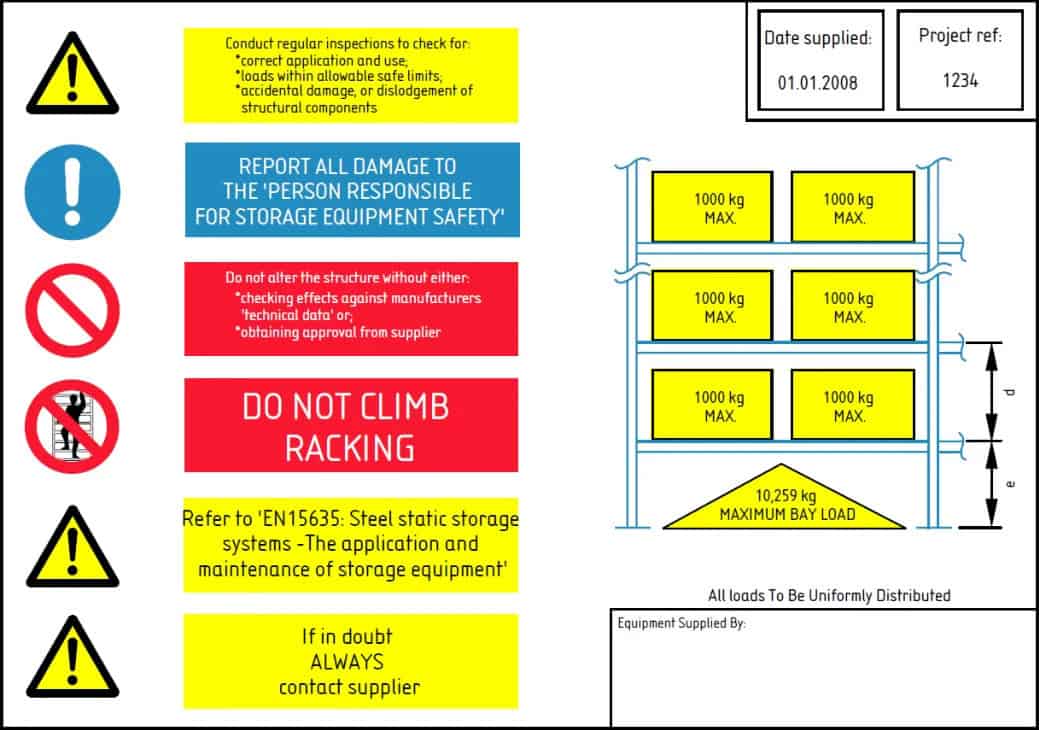

VNA racks can be built as high as the ceiling allows, which means pallets are loaded and unloaded at very high positions. Professional trucks used in conjunction with VNA racks are highly efficient and have the ability to ensure this is done safely. There are many different options when choosing a VNA racking truck, including a man-up truck, which enables the operator to move to the top with the pallet for improved visibility during high-altitude activities. For added protection to towering rear racks, backstops can be installed to prevent pallets from being accidentally placed on the edge, or anti-slump nets can be installed to close the back to secure cargo on pallets.

Why Is A Flat Floor Essential?

VNA racks must be installed on a completely flat concrete floor. Warehouse floors must meet required specifications including ultra-flat surfaces. VNA racks are usually higher than standard racks, and due to uneven ground, trucks may tip and tilt the racks at high altitudes, which is very dangerous.

What are the requirements of VNA racking for warehouse floors?

1. For logistics warehouses, the ground flatness of the narrow aisle (VNA) racking area is a very important factor, which directly affects the operational efficiency and operating costs of the warehouse. European standard EN25620-2008 has clear requirements for this. The ground level should not exceed 15mm from the reference point.

2. For the design of VNA narrow aisle racking system, in the drawing stage of warehouse design, it is best for the racking company to coordinate with the civil engineering design institute. In this way, it can be fully considered that the arrangement of the building columns does not affect the shelves, and the space is effectively used. It is also necessary to provide reasonable ground average load and concentrated load parameters according to the customer’s shelf layers and cargo weight.

3. Considering that the height of VNA racks is generally between 10-15 meters, the racking structure needs to be specially designed for earthquake resistance. If conditions are available, finite element analysis and calculation should be performed to select the rack structure.

4. Due to the narrow aisle, when the forklift travels in the roadway, the redundancy is very small, and the forklift guidance system must be considered. There are three types of choices at following depending on the VNA forklift selected.

1). 100mm angle steel guide rails are set on the ground on both sides of the aisle, and the guide wheels at the bottom of the forklift are used to clamp the guide rails to ensure the straightness of the forklift truck (beams need to be added at the bottom of the shelves, and the overall load of the columns will increase);

2). The forklift company lays magnetic lines of force on the ground in the middle of the aisle, and the magnetic guide guides the forklift to go straight in the aisle (no angle steel guides are required, and the goods at the bottom of the shelf are directly placed on the ground).

3). The secondary pouring cement of the angle steel rail is constructed by the civil construction party (the goods at the bottom of the shelf are directly placed in the secondary pouring layer of the rail to increase the impact strength of the rail).

Comparison of VNA Racking & Standard Selective Racking

The most common type of pallet racking system used in distribution centers is selective pallet racking. This is a multi-functional system suitable for various operating functions.

There are a variety of options within the selective racking to make this type of system the best fit for your space, SKUs and picking process. One of these options is a very narrow aisle racking system, commonly referred to as a VNA racking system. Read below to learn about the differences between standard selective racking and VNA racking system and find out what might be right for your operation.

Aisle Width

Selective racks with very narrow aisles will reduce your aisles from the standard 12′ to typically about 6′ to 6′-6″. The system still provides first-in, first-out storage and retrieval.

By comparison, the standard optional racking system is also a 1-deep racking system, but has a 12-foot or so aisle. This rack configuration also provides first-in, first-out selectivity. This is a low density high selectivity system.

Number of Pallet Positions

The VNA does have an advantage over the standard when considering the number of pallet positions obtained. With VNA, you get much more pallet positions than with standard lanes.

However, there are a few things to consider before converting to a very narrow aisle racking system. Keep in mind that it does require an investment in a turret truck, which is a bigger investment than a sit-on forklift. You may have to buy multiple trucks to cover these extra rack rows. Also, many companies put wire guides in these very narrow aisles to help avoid damage, which would be another expense.

However, if you have a low number of pallets of the same SKU and you need high selectivity, then a very narrow aisle racking system may be right for you.

Things to Consider If you Want to Switch to VNA

Extra Cost on Forklift

If you currently have a standard optional rack but think a VNA rack would be more beneficial to you, you’ll be happy to know you’re able to switch.

First, you have to take into account that you won’t be able to use your existing standard forklift with the system. As mentioned in the previous section, you will need a turret truck. This is a forklift capable of operating in these very narrow aisles.

Extra Cost on Racking

Once you’re sure this is doable, then you’ll want to go to a storage system vendor that offers you a very narrow aisle layout. Moving forward will require unloading the product, removing existing racks, reassembly and possibly adding as you will have more storage space available to add racks.

You should be able to use your current selective rack for most of this system. This of course depends on the condition of your current rack.