What is Drive-in Racking?

The drive-in racking adopts the pallet access mode, which is suitable for the storage of goods with few varieties but large scales. Drive-in racking is a type of racking that effectively improves the utilization rate of the warehouse.

How does Drive-in Racking Work?

Drive-in racking is composed of multiple connected aisles, which are both the place to store goods and the place for forklifts to drive through and work. Pallets that carrying goods are all stored on the support rails. The pallet placed first is in the deepest position of the racking, and the later placed pallet is much closer to the racking entrance. Forklift trucks are required to be used for loading and unloading goods in the drive-in racking system.

Components of Drive-in Racking:

Upright Frame: The upright frame is the most important part of the drive-in racking system. It provides the major support to the whole system. It is consisted of uprights columns and bracings.

Top Beam: The beams on the top part of the drive-in racking system are called top beam, they offer strength on the top of each bay.

Top Bracing: Top bracing works with top beams to connect the system on top of each bay. The parts are connected by buckles or nuts.

Double Support Arm: Double-side arms are the gadgets that hold pallet rails. They are anchored on the upright posts, which are mostly in orange.

Single Support Arm: Single-side arms, just like double-sided arms, are also used to provide support for the pallet rails. The only difference is that the needs of single-sided arms are much less than double-sided arms, since only the start bay and end bay require single-sided arms to hold pallet rail.

Support Arm Rail: The rails are where you lay your pallets on. You lay your pallets between two rails, where the pallets can be pushed into the deepest position of the system to leave empty space for new coming pallets. Without rails, the drive-in racking is unable to work.

Post Protector: Usually colored in yellow, most post protector are in bold color for forklift to avoid the vulnerable part of the racking system. Post protectors are mainly designed to protect the uprights for racking safety.

Floor Guide Rail: Floor guide rail is designed to guide the forklift drivers to move safely in the racking system. It can smartly and quickly stop forklift wheels before hit the racking system. This is additional component, but we suggest it used in each drive-in racking project.

Four Features of Drive-in Racking

- Drive-in racking system is one of the high-density pallet racking.

- Drive-in racking system follows Last In, First Out stock rotation rule.

- Drive-in racking system is ideal for storing goods with the features of high-volume and low-SKU.

- Drive-in racking system is not suggested to be designed more than 8 pallets lane depth.

Advantages of Drive-in Racking System

- Drive-in racking system can offer maximum pallet storage option.

- Drive-in racking almost eliminate all the unnecessary aisles, which brings more efficient use of space

- Drive-in racking system provides high-density goods storage.

- Drive-in racking system can be customized as to your pallet size and forklift size.

- Drive-in racking system is one of the most cost-effective storage solutions.

- Drive-in racking system can be integrated with all other racking systems to form a combination system.

Applications of Drive-in Racking

Drive-in racking system provides many advantages and it cut the use of additional aisles. The pallets can be easily loaded one by one and next to each other. In this case, drive-in racking system fits for goods with low SKUs but large quantity for each SKU.

- Food and beverage goods

- Agricultural goods

- Chemical goods and barrels

- Refrigerated warehouses

Tips of Note When Using Drive-in Racking

Be sure to check the pallets before they are on racking.

Be sure to check the pallet size before placing the goods on the racking. Make sure that the pallet size and rack rail width match. This point is very important. You can’t be sure that all the drive-in racking aisles in your warehouse are of the same width. Sometimes the pallets in using are in different sizes. Therefore, it is very necessary to do a good check-up. You can’t skip doing this process because it seems like a useless part. It would never be bad to be careful. In addition, pay attention to check whether the pallet is in good condition. If the bottom of the pallet is damaged or cracked, have it replaced quickly.

Be sure to operate in a right way.

Ensure centered load alignment between the rack uprights and verify that the pallet has been raised to the correct rail height prior to entering the rack. Driver should be clear that it would be better if the pallet which is going to be placed on the rail can be raised 1 to 2 inches higher than the rail before it is finally put on the rail. This is to avoid any push on the rail that could result in any risks of the system. Never drag or push the pallet on the rail. When backing up after placing pallets, be aware of potential forklifts and pedestrians in the aisle. You can press the forklift horn to remind people or vehicles in the area to avoid unnecessary accidents.

Make sure forklift fits the aisle width.

Make sure your drive-in racking system is custom made for your forklift size. And you have to be clear that your racking can only work with the forklift of the corresponding size. If your forklift is too big for your racking, it would be difficult for your forklift driver to work and failed to drive it into the aisle.

Drive the forklift slowly.

The entire process of operating drive-in racking system must be slow, do not drive in or out of drive-in rackings at excessive speed. Because the width between uprights is limited and crowded, it is very important to operate slowly and carefully to avoid colliding with any part of the system.

Extra protections are necessary.

Provide extra protection to the upright and arm at the entrance of the drive-in racking system, because these places are the places where forklifts often go in and out and are most likely to be damaged to cause collisions. On-going training provided to your warehouse forklift operators on proper loading and unloading of drive-in racking is necessary.

Maintenance of Drive-in Racking System

Check out the following tips to help you keep your warehouse in high-efficient condition:

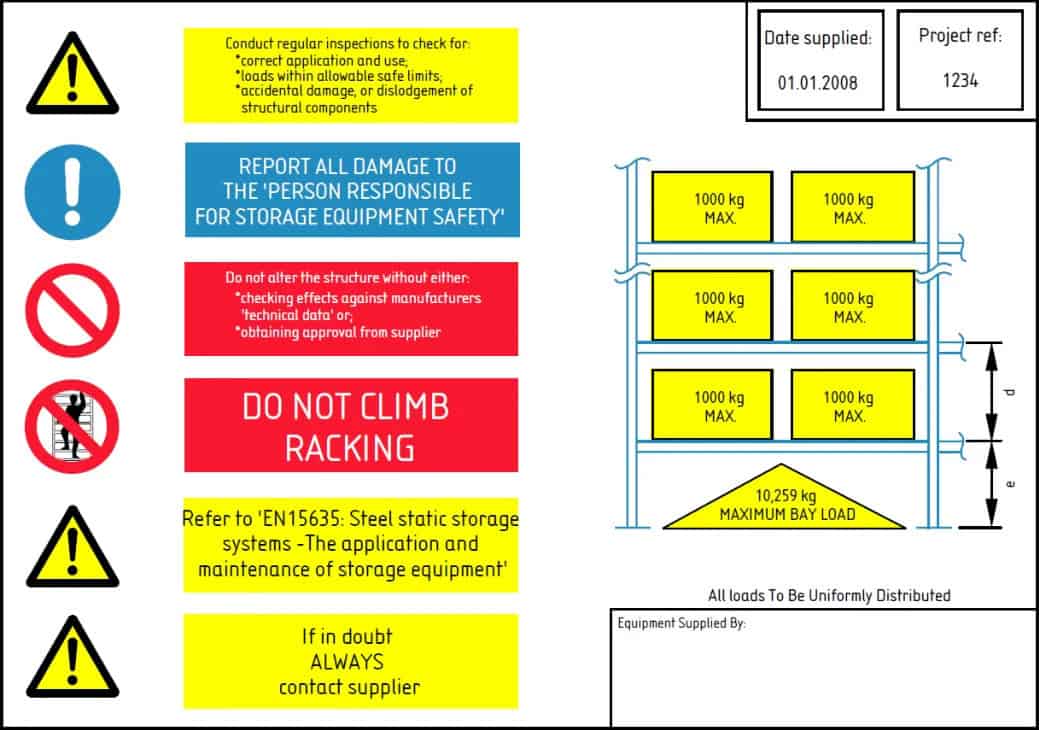

- Check out the different parts of the system are working properly on a regular basis. Report the damage related to any part of the system, like broken beam or uprights to the manufacturer or the supplier of your racking system. Check for safety locks on beams; any damaged or broken locks should be replaced immediately.

- To avoid the system metal getting rusted, check the powder coating of the metal parts and get them cleaned and painted regularly.

- Regular check for pallets condition, replace those with signs like cracks, breaks or severe damage.

- Make sure that all bolts, nuts, and other little hardware are all well tightened.

- Regularly train warehouse personnel on the correct use of forklifts and loading and unloading techniques to improve their awareness and sense of responsibility for maintaining a safe environment in the warehouse. Operating posts about safety operation instructions should be displayed at various points of the warehouse for warehousing personnel to see and adhere to.

Things to Figure Out before Designing a Drive-in Racking System

Pallet Size and Type

The size of the pallets directly affects the depth and height of the drive-in racking system. The weight of a single pallet should be recorded and taken down. The weight of the pallet and the weight of the goods together determine the range of the load capacity of each unit of drive-in racking. The type of pallet is selected according to the type of goods to be carried. If the carried cargo needs to be stored at a specific ambient temperature, or if the stored cargo is fragile and cannot be stacked, or the stored cargo has a shorter shelf life, they are all need to be taken into consideration before designing a drive-in racking system.

Order of Inventory Retrieval – LIFO or FIFO

Before designing a drive-in racking system, you need to determine the nature of the products you store. If you store products with an obvious shelf life and are date-sensitive, you’d be better off designing a first-in, first-out racking system. If you store products that are not date sensitive, then you are free to choose your racking delivery system. Both LIFO and FIFO work fine.

SKU / Pallet Count

The number of SKUs and the number of pallets per SKU in a facility play a large part in determining the type of pallet racking system you may need. If in your warehouse, the condition is like you have large SKU products and there’s only one pallet for each SKU, then you’d better organize a selective pallet racking system rather than drive-in racking system. While if most of your warehouse products are of the same specification, which means you have large quantity products while few SKUs, then drive-in racking system is suitable.

Warehouse Environment

The pricing of your drive-in racking system will fluctuate depending on the type of environment your storage products require. Products can be stored in a variety of different environments, including: Cold temperature(freezer), Controlled temperature (fixed temperature), Ambient temperature (products do not require a particular temperature). Food or other perishable items need to be stored at low freezing temperatures. Controlled temperature warehouses usually store some products that do not require freezing, but are best stored in a cooler environment, such as medicines, cigars, etc. There are many other products that are stored at normal temperatures, don’t have specific requirement for the environment temperature. If your products tend to be stored in a freezing environment, you may have to get ready to pay more for the racking system.

The reasons are as follows:

First, it takes longer time for workers to install your drive-in racking system under a super low temperature that is not suitable for men to stay.

Second, the metal parts of a drive-in racking system tend to get more easily to be rusted under a moisture environment, which means you may have to get them replaced more frequently compared to those under normal condition.

Building Structure

The size and layout of your warehouse determines how you design your drive-in racking system. First you need to determine which parts of your warehouse are reserved for the drive-in racking system. This determines how many rows your drive-in racking system can be arranged in total. You will also need to measure the height of your warehouse, which determines the max. height of your drive-in racking upright. The entrance and exit of your warehouse also affect the layout of racking in some extent. If you have multiple entrances and exits, you can even design your drive-in racking system as a drive-through racking system. This gives you more options. Therefore, it is necessary to understand the layout and size of the warehouse before designing the racking system.

Comparison of Drive-In Racking and Push-Back Racking

Push back pallet racking system is ideal for storing multiple pallets of the same SKU and are mostly preferable when Last-In-First-Out (LIFO) inventory management is followed. Drive-in racking system is also a high-density storage solution that enables storage of pallets in multiple horizontally and vertically arranged aisles. This maximizes use of available space and height in the warehouse. It also mostly follows the Last-In-First-Out (LIFO) inventory management.

Commons of Drive-In Racking and Push-Back Racking:

- Both of the two racking systems offer the best use of available warehousing space than most other systems.

- Both of the two racking systems increase product storage density by eliminating unnecessary aisles and are multiple pallet positions deep.

- Both of the two racking systems are good for storage of goods of the same reference, and with a low turnover.

Differences of Drive-In Racking and Push-Back Racking:

- Drive-in racking system can be designed into both FIFO and LIFO inventory management configuration. While push-back racking system can only support LIFO inventory management configuration.

- Push-back racking system allows for quicker and easier loading and unloading of pallets, since the pallet on the rack can be pushed into the deeper position, unlike the operation of drive-in racking, none push action is allowed.