Double-Deep Pallet Racking is widely used in various industries, such as paper making, plastic products, tobacco, food, packaging materials and other industries. The Double-Deep Pallet Racking system adopts four sets of racks to be arranged in the same line, with each two rows stand back-to-back, which effectively reduces the racking aisle. Each storage racking line can store twice as many pallets as the single pallet racking system can do, so the storage capacity of this kind of racking is much higher than that of the ordinary pallet racking system. The use of this racking system requires a special forklift to join. To pick up the goods on the second row, the goods in the front row need to be taken away to leave the room for the operation. This is similar as the drive-in racking system. It is difficult to make the goods first in first out. Therefore, in order to improve the utilization rate of the warehouse, it is generally necessary to consider storing the rear racks first, and then store the front racks. The configuration cost of the Double-Deep Pallet Racking system is the lowest of all warehouse racking systems.

What is Double-Deep Pallet Racking System?

Racking is one of the most frequently used tools in warehouses. Nowadays, you can see the types of the goods stored in the warehouse are increasing, and the shapes of the goods are various, these all lead to more options of warehouse racking systems. Various kinds of racking systems have been created and applied in the warehouse. Double-Deep Pallet Racking System is one of them. The Double-Deep Pallet Racking System is an upgraded version of the Single-Deep Pallet Racking System, with the similar and simple structure as normal pallet racking system. Compared with ordinary pallet racking system, Double-Deep Pallet Racking System saves the space of forklift aisle. Therefore, the Double-Deep Pallet Racking System can store more products in the same warehouse space. This kind of racking is suitable for companies require for high-density storage. It is widely used in tobacco, food and beverage, packaging and other industries. The specifications of such racking can also be customized according to the needs of customers.

Features of Double-Deep Pallet Racking System

- It is suitable for warehouses with low or medium inventory turnover rate.

- It provides the storage solution that ordinary pallet racking cannot do. It doubles the inventory than the common pallet racking system.

- It needs to be equipped with special forklifts in daily operation. The width of forklift aisles generally needs to be as wide as 3.6 meter.

- Same as the drive-in racking system, it is not very convenient to access the goods in the rear row. The access operation can only be carried out after the corresponding goods in the front row are taken away or shifted. The access of goods is difficult to be first in first out. In order to improve the utilization rate of the warehouse, it is necessary to consider storing the rear racks first, and then store the front racks.

- When the goods are shipped, try to remove the goods in the front and rear rows at one time. If there are too many cases that cannot be sold at one time, it may affect the inventory utilization rate.

Differences Between Double-Deep Pallet Racking System and Regular Pallet Racking System

Racking is used for storing inventory in the warehouse. We have all different types of racking options to be applied in our storage place. You can always configure the most efficient racking system in your warehouse based on your specific needs. Whether you apply a single-type racking system or combined racking system, all of them can be calculated and customized. The components of most pallet racking system include uprights, beam, bracing and blots. All these works together to provide the security support of the whole system.

Double-deep racking system is upgraded from single-deep racking system, they are similar in the structure. The only difference is that double-deep racking system are configured with each two rows back-to-back, while single-deep system is only one row.

So, what is the strength of ordinary pallet racking system?

Features of Ordinary Pallet Racking System

- The Single-deep Pallet Racking System is one of the most common and widely used racking system in the warehouse. It is suitable for the vast majority of product goods.

- The storage operation is carried out by a forklift, which has high work efficiency and short operation time. This reduces the labor intensity of employees.

- The height of each shelf can be adjusted freely, so that it can meet the space requirements of different sizes of goods.

- Usually, the goods are stored on the shelves after being assembled by unit container equipment such as pallets or storage cages.

- The forklift can reach any cargo space for storage operations. The selectivity is 100%, and the operation is convenient and fast.

Things to Consider Before Deciding an Exact Racking System

The Density of Goods Storage

In the single-deep racking system, the aisles for forklifts are wide, so the density of goods storage is not high, and the space utilization rate of this system is generally about 30%~35%. While in the double-deep racking system, the forklift aisle is narrow, therefore, the storage density is high, and the space utilization rate is relatively high, which can reach about 45% to 60%.

Equipment Needed for Storing Goods

The single-deep racking system has a relatively wide aisle, so the normal forklifts can be used in this system; While the aisles of the double-deep racking system are narrower, so they need to be equipped with special forklifts which means a higher cost.

The Widths of the Aisles

The width of the single-deep racking system aisle generally needs to be at least 2.4m or more and may even be required to reach 3.6m. The space utilization of this type of system is average. The width of double-deep racking system aisles is much narrower than the single-deep racking system aisles. Generally, it is about 1.6m-2m. The aisles are narrow, and the number of aisles is fewer. So, the space utilization rate of this type of system is significantly improved.

Goods Selectivity Rate

In the single-deep racking system, the forklift can freely access to any pallet on the racking. The selectivity of this system is 100%, which can realize the first-in, first-out goods turnover order. And the operation of this system is very convenient and fast. The double-deep racking system is not so convenient because the double-row racks are configured together. To retrieve the rear pallet goods, the front row must be removed first. With a selectivity of 50%, it is difficult to achieve first-in, first-out. But the space utilization is more efficient in this system.

Consider Your Needs

When deciding on which pallet racking system to use, enterprises should first collect their own requirements for racking, and then evaluate their own warehouse structure and environment, and finally choose the most suitable racking type. The single-deep racking system is currently one of the most widespread and widely used racking system, suitable for most warehouses for storage of goods, high goods selectivity rate, easy to operate. The double-deep racking system has a simple structure and high storage capacity, which can effectively alleviate the storage requirements that the regular pallet racking cannot meet. This kind of racking is widely used in tobacco, food and beverage, packaging, paper industry, plastic products industry and others. The specific size specifications need to be determined by professionals according to the characteristics and requirements of the company’s goods and warehouses.

Can Double-Deep Pallet Racking System Be Used in Cold Chambers?

Cold Chambers refer to warehouses where the ambient temperature is below zero. The temperature of cold chambers is generally maintained at minus 5 degrees to minus 30 degrees, so it is different from normal-temperature warehouses. The storage equipment for storing goods in the warehouse is required to be able to adapt to such an environment. There are many storage racking systems that can be used in cold storage, such as drive-in racking system, radio shuttle racking system, etc. So, can double-deep racking system be used in cold chamber? Let’s take a look.

YES, double-deep racking system can be used in cold storage. However, it is necessary to consider whether the cold storage has high requirements for goods access efficiency. Because the cold storage temperature is low, the operating cost is also high. If you want to achieve a higher level of storage capacity and access efficiency of goods, it is recommended to choose a high-density racking system, such as a radio shuttle racking system. In short, the double-deep racking system performs well in terms of space utilization, load capacity and rack stability, and can also be used in cold storage. And the price of this system is also more advantageous than other high-density racking systems. If the enterprise does not have very high requirements for the access efficiency, or limited budget for other high-density racking systems, choosing the double-deep racking system is also a good choice.

Differences Between Double-Deep Pallet Racking System and VNA Racking System

Both the VNA Racking System and the Double-Deep Pallet Racking System are evolved from the pallet racking system and are both a kind of heavy-duty racking system. Due to some of its similarities, it is often easier to confuse these two types of racking. So, what is the difference between these two racking?

The biggest feature of VNA Racking System is that the aisle is much narrower than the general pallet racking aisle. It is about 1600mm-2000mm, which greatly improves the space utilization rate of the warehouse. Because of this, VNA Racking System is favored by many enterprise warehouses. This racking system needs to be equipped with a special forklift to cooperate with it, which is another feature of this system. Because the aisle is relatively narrow, this requires the forklift driver to be experienced, the driving skills should be high and mature, and the work attitude should be careful and cautious.

In the Double-Deep Pallet Racking System, the height of each level is not very high, the overall racking height can reach 8 meters, and the ground utilization rate is high. Suitable for warehouses with low pickup rates. Double-Deep Pallet Racking System is derived from pallet racking system, with simple structure and high storage capacity.

Racking Aisle Width

The way how the racking system is placed in a warehouse can affect the warehouse space utilization. The narrower the aisle is, the higher the storage space utilization could reach. However, when planning the layout of warehouse racking, it is necessary to consider the management method and storage way – whether you need first-in, first-out goods turnover order, whether you need forklift access and so on. Therefore, there is no certain standard for how wide the aisle should be kept between racking, while it should be determined according to the exact situation and your actual storage needs.

When you opt for manually accessing the goods, the width of the aisle can be set anything between 80mm and 120mm. When you opt for forklift accessing the goods, please refer to the model of the forklift. The smallest forklift should leave 2 meters aisle width, usually 2.4m or 2.6m, and some large forklifts may need to leave 4 meters for the aisles.

At the same time, the number of racking aisles can be reduced according to the requirements of the management method. For example, Double-Deep Pallet Racking System reduces half aisles than single-deep racking system. The Drive-in racking system is a whole-building racking with fewer aisles. However, the goods selectivity rate of these two kinds of racking cannot reach 100%, which is suitable for warehouses with batches of first-in last-out.

Q&A Regarding Double-Deep Pallet Racking

What are the components of double-deep pallet racking system?

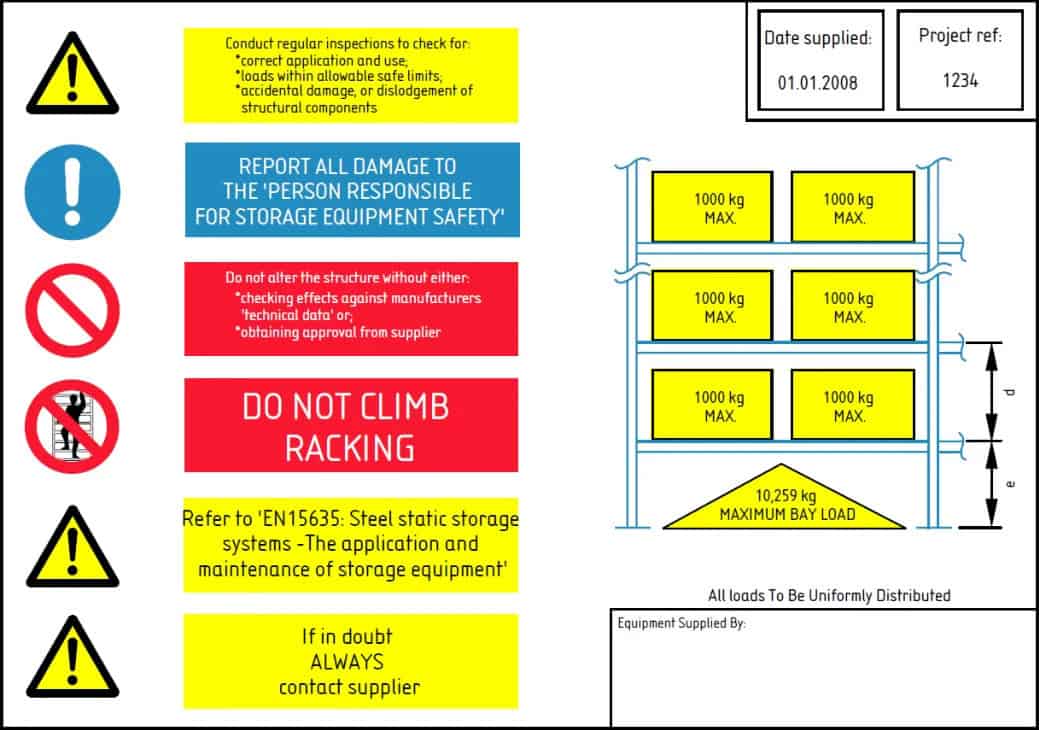

Double deep pallet racking has the same structure as adjustable pallet racking, only that its layout is different, so the racking components are the same or very similar. Double deep storage systems will therefore consist of a simple structure made up of beams, frames and other accessories such as support bars or mesh decks. This system also has safety elements such as frame and upright protectors, fall-arrest meshes, reinforcements and pallet backstops.

What is backstop used for in the system?

There are various complementary elements in the double-deep pallet racking system that enhance the safety of the installation, such as the protection meshes and upright protectors. The pallet backstops are just one of them. They are preventive safety backstops for double deep pallet racking. Their objective is to prevent the pallet from falling due to an inappropriate man oeuvre.

How do I know whether double-deep pallet racking system fit my warehouse?

Double-deep racking work well in the following conditions:

- Long or medium-term shelf life as a result of the LIFO (Last In, First Out) turnover demand.

- Dry storage inventory without any expiry concerns.

- Double-deep option for cold storage that minimizes utility costs and maximizes storage.

- Double-deep racking maximizes the amount of storage space in your facility, while the improved accessibility and flow benefit the efficiency and productivity of your workers.

When should I avoid double-deep pallet racking system?

- When you have lots of SKUs with single pallets in stock, double deep racking does not make sense.

- LIFO inventory management may not be desirable.

- Reduced SKU’s accessibility may not be desirable.

- When you need to perform order picking from pallets, this is not the system to use.

- When pallets are accessed frequently for picking and then put away again, this is not the system to use.

I am growing inventory in my warehouse, should I upgrade my existed racking system to double-deep?

We can confidently say that the most important reason for moving to a double deep racking system is to increase storage space efficiency – could be up to 10-15%. So, YES, if you have more goods to store at a time, we suggest you upgrade your system to double-deep racking system. With the help of double-deep racking system, the number of your racking access aisles can be reduced. Double-deep pallet racking system is an excellent system for storing multiple pallets of the same product. It is also less expensive than push-back pallet racking which is also a high-density racking system.

Before installing double deep racking, it is important to consider the type of product being stored and the number of SKU. A double-deep racking system is the best for fewer SKU of products but with long shelf lives.